Stripped and Broken Screws on Guitars

Solid body electric guitars typically use a variety of wood screws to secure the different components such as tuning machines, strap buttons, bridges, and pickguards to the body. The use of common wood screws provides a quick and secure method for installation and the eventual removal of the hardware when required. Though typically reliable, factors such as incorrect installation and storage, or heavy use, can lead to the need for maintenance and repair.

For best results, we strongly advise clients to allow us to assist with any repairs or modifications. Please contact us for an evaluation. However, we realize that guitarists sometimes choose to perform installations using such a familiar item as wood screws at home. Of course, simple does not always mean easy! We believe that an ounce of prevention is worth a pound of cure. Below are a few simple tips to avoid stripped and broken screws or mounting holes on your instrument.

7 tips to avoid stripped or broken screws

- Pre-drill a pilot-hole to the appropriate width and depth before installing the screw

- Apply a small bit of wax onto screw threads before installation

- Use the correct screwdriver to match the screw head type and size

- Stop and back out the screw if you meet heavy resistance or upon hear creaking sounds

- Tighten screws as soon as they become loose

- Replace screws that are rusted or have a stripped adjustment head

- Remove guitar straps before placing the instrument in its case

Repairing Damaged Guitar Screws

Dowel and Pilot A Worn Strap Button Hole

It is common for instruments to arrive in our shop with stripped strap button or strap-lock screws, and/or worn out mounting holes in the body. This type of damage seems to occur most often on instruments that have strap locks. This is due to both the extra stresses placed upon the button by these devices during use and the players failure to remove the strap before placing the instrument back in the case.

Clients are often seemingly unaware that the button is loose until it either falls out completely or the screw breaks! This sometimes leads to the instrument falling to the floor and the need for a larger repair. Fortunately, when dealt with early, this is a fairly simple problem to fix.

When a wood screw becomes loose, or is otherwise incorrectly sized, we say that it has “play” in it. This means that the screw can be moved back and forth, perhaps only very slightly, within the hole.

If there is play in it, when the screw is stressed under a load, the side to side movement wears out the wood further overtime. The hole become oblong in shape and continues to expand under the stress placed upon it.

The typical “roadie repair” is to remove the screw and cram in some toothpicks, to shim the hole, before reinserting the screw. While this works in a pinch, it is not an effective long term solution.

For a reliable repair, we will fill the damaged hole and start again.

First we remove the damaged button. In some cases the screw itself becomes bent and requires replacement before reinstallation.

Then we drill out the hole to return a rounded shape and enlarge it slightly. The added width ensures that, once plugged, there will be plenty of solid wood for the new screw to grip into.

Next we will make a custom hard wood dowel and glue it in place to plug the old hole.

After the glue dries we will trim away any excess material leaving the plug flush with the body.

Having reestablished a secure location for installation, we drill a new pilot hole for the strap button. Now the strap button is ready for reinstallation. Once tightened snug, this bass is good to go!

A good setup is all thats left to do before releasing the instrument back to its owners care.

Extracting An Embedded Screw From A Guitar

It was all going so smoothly, right up until it wasn’t! It happens to us all at one time or another. Stripped or broken screws most often occur when installing a screw into a newly drilled hole. The small screws used for mounting tuning machines and string guides are especially prone to breakage. However, this occasionally happens to larger screws such as those used to mount bridges, tailpieces, and strap buttons too.

This Fender Telecaster replacement neck is made of hard maple wood. The string guide mounting screw broke during installation and we were tasked with repairing it.

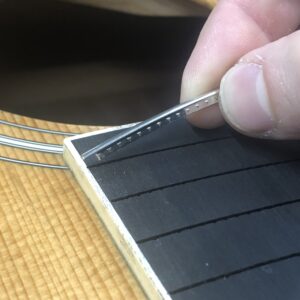

Since the screw broke nearly flush with the wood, there was no way to grip the screw and back it out. Removal required extracting it.

To remove this screw we used a special hollow drill bit and a guide to bore out the wood around the screw. Once the wood around the screw has been removed, the screw has nothing left to bite into and it can simply be lifted out of the hole.

In this photo we have removed the broken screw and are holding the broken screw next to the hole for scale.

Next we made a custom dowel to fill the hole that we created and glued it in place. After the glue dries, the string guide can be installed using a new screw.

Erik Salomon - Calico Guitarworks Owner / Head Technician

Tech Talk articles are part of an ongoing effort to provide clear and detailed answers to common questions about guitar maintenance, modifications, and repairs.

While not intended as a step-by-step guide to servicing your own instrument, we hope that you will find value in the information provided.

Great Repairs Start With The Right Parts

Many of the parts mentioned in our blogs are available for purchase at:

GuitarRepairParts.com

Enter the code "TechTalk10" at checkout for 10% off your first order.

About Calico Guitarworks

Calico Guitarworks is the area’s premier destination for fretted musical instrument care and maintenance. Owned and managed by Erik Salomon, the shop is dedicated to providing quick, honest and reliable service. The staff at Calico Guitarworks has a combined 25+ years of professional guitar repair experience. Sharing the knowledge that we accumulate in this focused pursuit is at the core of what we do. Learn more About Calico Guitarworks, explore our Frequently Asked Questions, or Contact us with a specific request.