Fret Work: Level, Crown, And Polish

Before a setup can be performed on a guitar or bass, it is crucial that the instrument’s fretwork be in good shape; The frets should be level relative to one another, with a nice rounded profile and smooth playing surface. This is especially important for players that are sensitive to string buzzes, have a discerning ear for intonation, or that prefer the string action to be set very low.

What Is A Level Crown and Polish?

This procedure is often interchangeably referred to as: “fret leveling”, “fret milling”, “level, crown, and polish”, “grind and Polish”, a “fret dressing”, or simply a “G and P”. All of these terms generally refer to the same task and concern the playing surface of the frets. The fret ends may be addressed separately or at the same time via a fret end dressing.

Poorly Executed or Badly Worn Fret Work Can Lead To:

- Buzzing strings

- "Choked" Bends

- Dead Spots

- Poor Intonation

- Lack of Sustain

- Increased Difficulty Playing Fast Runs

- Awkward "Neck Feel"

What Causes Uneven Fretwork?

New Instruments Often Need The Frets Leveled

During instrument assembly, frets are installed into slots that are cut into a wooden fingerboard. Even in expert hands, it is virtually impossible to press or hammer 20 or more frets in a perfect plane with one another. Due to demanding production quotas, many instrument manufacturers do only a cursory job of fret leveling after installation. On student grade instruments, this crucial step is often seemingly overlooked altogether!

After these instruments leave the factory, they are placed in shipping containers and trucks to travel across states, often entire continents, before reaching an instrument retailer for sale. Once at the dealer, guitars may spend several seasons on a wall or in a warehouse before purchase. While all this is taking place, changes in climate and humidity can cause the wooden fretboard to swell and contract, potentially loosening and unseating the metal frets in the process, throwing them out of level.

A high string action can mask issues with the fretwork that become glaring apparent once the string height is set lower. Even with the frets in less than perfect condition, a guitar may play acceptably with the comparatively high action that many instruments have at the time of purchase. However, since many discerning players demand a higher degree of playability from their instrument, preferring string action to be set below the manufacturers spec., a fret leveling is the best way to remove these inconsistencies and allow the instrument to reach its full potential.

Leveling Worn Frets On Used Guitars

Besides all of the conditions outlined above, used instruments are further subjected to the wear and tear of use. In addition to pronounced fret movement that can occur from prolonged exposure to humidity fluctuations, over time, the friction of pressing down metal strings against metal fret wire can create flat spots and grooved impressions where the strings make contact. Fortunately, many times this damage can be removed through a level crown and polish. However, in extreme cases, the frets become so worn down that they require replacement. For this reason, we highly recommend inspecting the frets before purchasing a used guitar or bass.

Loose Fretwork

Loose fretwork is a common problem regardless of the model or age of the instrument. Since the frets are press fit into the wooden fingerboard, the quality of the fit is extremely important.

While the video shown is an extreme example, even micro movements of the frets within the slot can have a profound impact on the instrument’s playability.

Before the frets can be leveled, it is extremely important that they be well seated in the slot. The severity of mismatch determines the process necessary to correct it; slightly loose frets can often be secured in position with glue, while extremely loose fretwork may require a refret for a secure fit.

Performing A Fret Level, Crown, and Polish

Shown here is a Fender Stratocaster with frets in need of repair; they are heavily grooved and pitted. In order to get the best playability out of the instrument, the customer elected to have them dressed.

Leveling The Frets

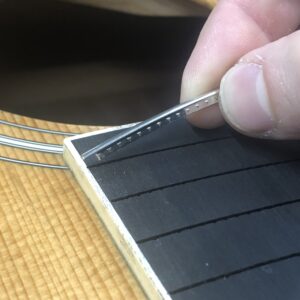

After inspecting that all of the frets are well seated in the fretboard, a steel leveling block is used to remove material from the fret tops. Filing with even strokes across the neck, the high spots are hit first and low spots will remain untouched.

Using a trained eye, we carefully remove material until all of the frets on the guitar neck are the same height. While this process does make the overall fret height a bit lower, typically only a few thousandths of an inch are removed overall. For most players the perceived change in fret height is imperceptible and far outweighed by the benefits of properly leveled and dressed frets.

Crowning The Frets

Once the frets are level, they are left flat, scratched, dull, and in short: unplayable.

We remedy this through the tedious process of “re-crowning”. We re-shape the profile of each fret individually until it achieves a “crowned” profile, leaving a thin line down the center where the string will make contact.

Polishing The Frets

With the frets now leveled and crowned, the polishing process brings the frets to a high shine.

Highly polished frets allow the player’s hands to move faster across the fretboard and make string bending feel much smoother an easier.

After re-checking the work to ensure that it is true, the guitar is ready for setup. With the frets in order, we should have no problem getting a nice low action, with proper intonation and buzz free bending on this guitar!

Erik Salomon - Calico Guitarworks Owner / Head Technician

Tech Talk articles are part of an ongoing effort to provide clear and detailed answers to common questions about guitar maintenance, modifications, and repairs.

While not intended as a step-by-step guide to servicing your own instrument, we hope that you will find value in the information provided.

Great Repairs Start With The Right Parts

Many of the parts mentioned in our blogs are available for purchase at:

GuitarRepairParts.com

Enter the code "TechTalk10" at checkout for 10% off your first order.

About Calico Guitarworks

Calico Guitarworks is the area’s premier destination for fretted musical instrument care and maintenance. Owned and managed by Erik Salomon, the shop is dedicated to providing quick, honest and reliable service. The staff at Calico Guitarworks has a combined 25+ years of professional guitar repair experience. Sharing the knowledge that we accumulate in this focused pursuit is at the core of what we do. Learn more About Calico Guitarworks, explore our Frequently Asked Questions, or Contact us with a specific request.