Electric Guitar Bolt-On Neck Resets

Shimming a Bolt-on Neck Guitar

When performing a setup on a bolt-on necked electric guitar, shims are a way to quickly adjust the angle at which the neck joins the body, facilitating the desired action adjustment.

In our shop, we commonly find improvised shims installed in the neck pocket. They range from purpose-built plastic shims like those pictured at the top of the page, to a hodgepodge of items like sandpaper, cardboard, and/or guitar picks.

The idea behind this practice is that placing a piece of material near one edge of an otherwise flat neck pocket causes the neck to sit at an angle once it is screwed down on top of it; The side with the shim installed will be higher than the side without. Technically speaking, this is a basic neck reset.

Crude shims are effective for changing the neck angle, but risk unintended consequences:

This style of shimming prevents the bottom of the neck from evenly contacting the entirety of the neck pocket. There will inevitably be a gap between the shimmed and non-shimmed ends.

This gap adds torsion and the neck will eventually flex under the pressure. The video shows the bottom of a bolt-on neck that is no longer flat after years under pressure. Over time, necks shimmed in this haphazard way are more likely to experience issues in their upper register, often requiring fretwork or refret to counteract.

The Fender Micro-Tilt

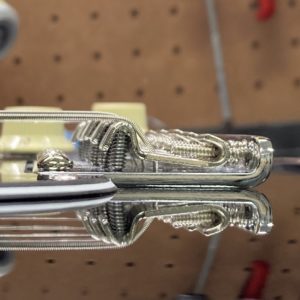

The Fender Micro-Tilt was introduced in 1971. It has been widely used over the years, including select models in Fender’s current lineup.

The Micro-Tilt is a built in device for changing the neck angle. The neck angle can be increased via an Allen key adjusted set screw, attached to the body, that presses against a metal plate installed on the underside of the neck.

While the Micro-Tilt works as advertised, making short work of a neck-angle adjustment, unfortunately, they suffer from the same pitfall as the improvised shims that are ubiquitous on non Micro-Tilt equipped instruments: The neck heel loses contact with the bottom of the pocket.

Full Pocket Length Neck Shims

When adjusting the neck angle of bolt-on neck guitars, we prefer to make make full length, angled, shims. This style of shim eliminates the gap that exists when using the previously derived methods. Though requiring a bit more effort up front, they facilitate a more stable attachment and minimize the potential risk of costly repairs down the road. This style of shim is reminiscent of the design used in the NT neck joint of Taylor acoustic guitars.

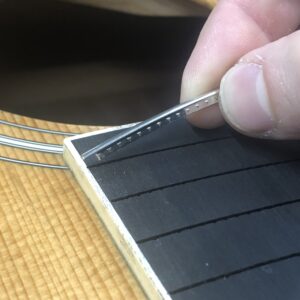

Here we are using a pre-tapered maple shim that is purpose built for this job. The shim gets progressively thicker across its length by a consistent amount; In this case, 1/2 degrees.

Using these pre-started shims makes a quicker job, as the thickness sanding has already been done for us.

To fit it, we first cut the blank to match the dimensions of the neck pocket. Since it covers the entire surface area of the neck pocket, it can provide a sturdy, but tapered, base upon which to install the neck.

Next we locate the position of the screw holes and create openings in the shim so that the neck mounting screws will pass through unobstructed while tightening the neck down into the pocket.

Finally, we added a little bit of aged lacquer to the edges of the shim to protect it from moisture and help it to blend in with the baked maple neck of this guitar.

Notice that the shim is thicker towards the bottom of the photo than it is at the top. This taper is what changes the neck-angle.

Reverse Tapered Shims

The most common reason to shim a neck is to increase the neck angle, facilitating lower action. However, sometimes instruments require a shallower angle.

Sometimes, even with the saddles set to their highest setting, the action in the upper register is still too low. This is a perfect candidate for a reverse tapered shim in the neck pocket.

Shimming for a shallower angle is common on Fender Stratocasters when the player prefers to have the tremolo bridge set flush to the body, or when an instrument has been assembled from miscellaneous parts that were not perfectly compatible.

The process for installation is similar to , the above outlines, except this time we are using a different sized shim and installing it with the thicker side towards the outside edge of the pocket instead of towards the pickup.

When finished, the larger taper does make the shim a bit more visible at the heel than when going the other way. Fortunately, by painting the edges, it can be made to blend in reasonably well.

Making Tapered Shims

Some instruments, like this Fender Mustang Bass, have a neck pocket shape that is incompatible with the available pre-tapered shims. In these circumstances, we use our thickness sander to make our own out of a piece of maple.

Though making the shim from scratch requires extra tools and a bit of added work, the benefits are worth it.

Neck Too Narrow For The Pocket

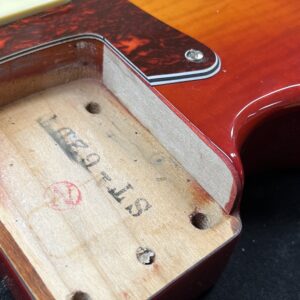

When combining parts that were not designed together, fit issues are not uncommon. A neck and body that were made by different brands, in different factories, or at different time frames, are liable to have different specs. This is an important consideration with “parts-o-casters” or when necessity requires fitting a modern replacement neck onto an old body.

If the neck is narrower than the pocket, a gap will be present along the side. The gap puts added stress on the bolt attachments and makes it difficult to properly center the strings.

A poorly centered neck can cause the E string to fall of the edge of the fretboard in the upper register.

If the neck is able to shift around in the pocket, a stable setup is all but impossible.

Installing a shim can help support the neck and guide it in the direction necessary for proper string alignment over the fretboard.

We have glued it to the side of the pocket and added a touch of color to help it blend into this cherry sunburst finish.

With the neck remounted, the gap is gone and there is no more play in the pocket. This quick repair, while not invisible, makes the instrument much more serviceable.

Using tapered shims in this way, is effective, secure, fast, and easily reversible if and when the need should arrive. They are often an integral piece to getting a bolt on neck guitar dialed in just right.

Erik Salomon - Calico Guitarworks Owner / Head Technician

Tech Talk articles are part of an ongoing effort to provide clear and detailed answers to common questions about guitar maintenance, modifications, and repairs.

While not intended as a step-by-step guide to servicing your own instrument, we hope that you will find value in the information provided.

Great Repairs Start With The Right Parts

Many of the parts mentioned in our blogs are available for purchase at:

GuitarRepairParts.com

Enter the code "TechTalk10" at checkout for 10% off your first order.

About Calico Guitarworks

Calico Guitarworks is the area’s premier destination for fretted musical instrument care and maintenance. Owned and managed by Erik Salomon, the shop is dedicated to providing quick, honest and reliable service. The staff at Calico Guitarworks has a combined 25+ years of professional guitar repair experience. Sharing the knowledge that we accumulate in this focused pursuit is at the core of what we do. Learn more About Calico Guitarworks, explore our Frequently Asked Questions, or Contact us with a specific request.