Planing A Bridge

Restoring Playability When A Neck Reset Isn't An Option.

While a neck reset is often the ideal solution for restoring a proper setup, the unfortunate reality is that most guitars that need a neck reset will never receive one. In other posts, we’ve covered the reasons for, and the process of, resetting guitar necks on various types of glued neck joints (e.g., dovetail, mortise and tenon, hybrid neck joints).

For many budget or mid-range instruments—especially those without a highly repairable bolted neck joint (like the Taylor NT neck)—the cost of a neck reset can far exceed the instrument’s market value.

With this in mind, we want to explain a more economical and effective method for restoring playability to a guitar that might otherwise be relegated to the closet: Bridge Planing.

Bridge Planing: When and Why?

Before diving in, it’s crucial to understand the context. Bridge planing is a permanent alteration that is generally considered taboo for collectors. This technique is exclusively reserved for:

- “Player’s Grade” Instruments: Guitars with significant use, wear, and tear where the primary goal is functional performance, not collectible value.

- Instruments with High Sentimental Value: Guitars the owner loves, where the cost of a full reset is prohibitive, but the guitar must be saved.

- Economically Viable Solutions: This is a cheap solution for a cheap instrument (or one that plays like one) that deserves to be played again. It is never considered for a vintage or collectible instrument.

Key Considerations

For bridge planing to be a viable option, the guitar’s current bridge height and neck angle must fall within certain functional parameters. The amount of material that can be removed is limited by the bridge’s structural integrity. Therefore, this technique typically allows for a much smaller adjustment to the neck angle than a neck reset.

The Planing Process:

Bringing a Working Martin Back to Life

This particular low-end Martin came into the shop with a severely underset neck. As a result, the string action was excessively high off the fretboard, and we did not have enough available saddle height left for adjustment.

The owner uses this instrument for rugged outdoor summer bar and restaurant gigs. After years of heavy use, it required significant work: high action correction, bracing reglued, a partial re-fret, and an output jack replacement. When tallied, the combined price of the necessary work far exceeded the instrument’s market value.

After a thorough conversation, we decided that instead of replacing it, we would use more economical means to return the instrument to professional-use status.

Measurements and Benchmarks

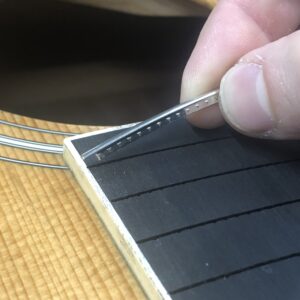

First, we measured to determine the required adjustment. As you can see in the photo, our straight edge falls well below the top of the bridge. To address this, we calculated that we needed to lower the bridge by about 1/16″ to correct the saddle plane and achieve the client’s desired string height.

Given that Martin has been known to use varying bridge heights, and this bridge was on the taller side to start, removing this amount of material will not leave the bridge dangerously thin.

To set a visual benchmark, we drew a pencil line where the saddle currently met the bridge. This line is visible in the photo above. We then removed the saddle, placed a temporary shim underneath that was equal to the amount of material we want to remove, and then marked the height again. This gave us a clear visual target for material removal.

Material Removal: The Planing

After protecting the guitar top with a custom-made caul, which also comes in handy for bridge reglues, we used a palm plane to remove the bulk of the unwanted material. We took care to maintain the original curvature and shape of the bridge surface throughout this process.

Once we got close to our line, we switched to coarse sandpaper on a cork block to fine-tune the shape and remove any minor gouging caused by the plane.

After rechecking with our straight edge, we can see that the bridge height is just about where we want it. (note how much more saddle is showing vs. the previous example)

Enhancing Break Angle and Pin Seating

To maximize the string tension (or “break angle”) over what would still be a lower-than-ideal saddle, we also ramped the bridge pin holes. Ramping involves extending the string slot forward, ensuring the string tension is focused directly onto the bridge plate and saddle.

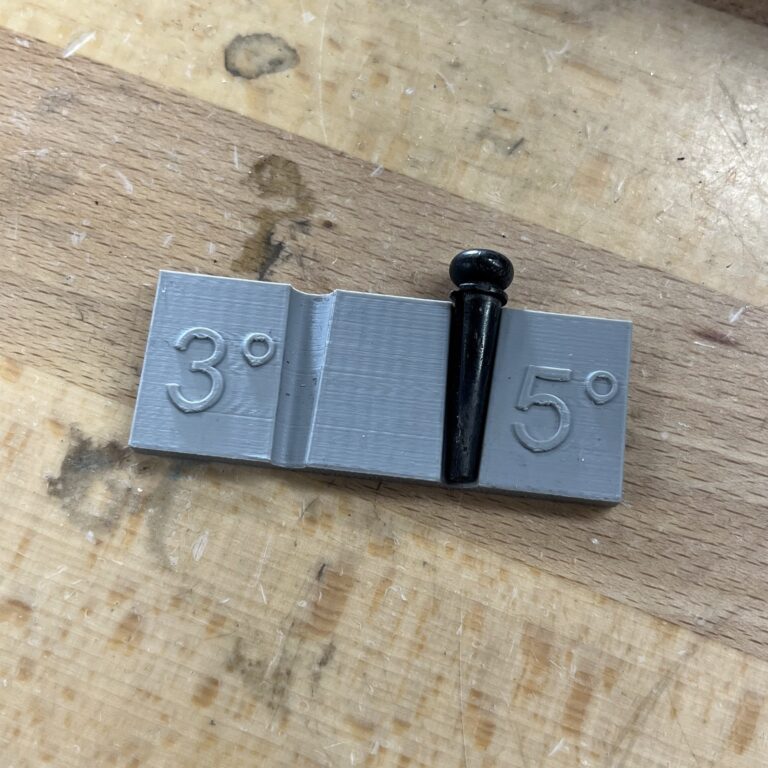

Since the bridge pin holes are tapered, removing material from the top of the bridge made them slightly undersized. They had to be reamed back to the correct taper and size to ensure the pins seated properly.

This particular guitar has 5 degree tapered pins, so we used a matching reamer to ensure a snug fit. It only takes a few turns to reseat the pin.

Finally, we re-chamfered the top of the bridge pin holes using a countersink bit. This provides a more polished look, allows the pins to seat better, and prevents wood tear-out during pin installation and removal.

Final Sanding and Polishing

After a bit of final sanding and reconditioning, this bridge is looking better than when it left the factory! Once a new saddle is fit, this guitar will back in shape, playing smoothly, and ready to head back to work!

Erik Salomon - Calico Guitarworks Owner / Head Technician

Tech Talk articles are part of an ongoing effort to provide clear and detailed answers to common questions about guitar maintenance, modifications, and repairs.

While not intended as a step-by-step guide to servicing your own instrument, we hope that you will find value in the information provided.

Great Repairs Start With The Right Parts

Many of the parts mentioned in our blogs are available for purchase at:

GuitarRepairParts.com

Enter the code "TechTalk10" at checkout for 10% off your first order.

About Calico Guitarworks

Calico Guitarworks is the area’s premier destination for fretted musical instrument care and maintenance. Owned and managed by Erik Salomon, the shop is dedicated to providing quick, honest and reliable service. The staff at Calico Guitarworks has a combined 25+ years of professional guitar repair experience. Sharing the knowledge that we accumulate in this focused pursuit is at the core of what we do. Learn more About Calico Guitarworks, explore our Frequently Asked Questions, or Contact us with a specific request.